- 2714

- 0

APR 強化汽門彈簧

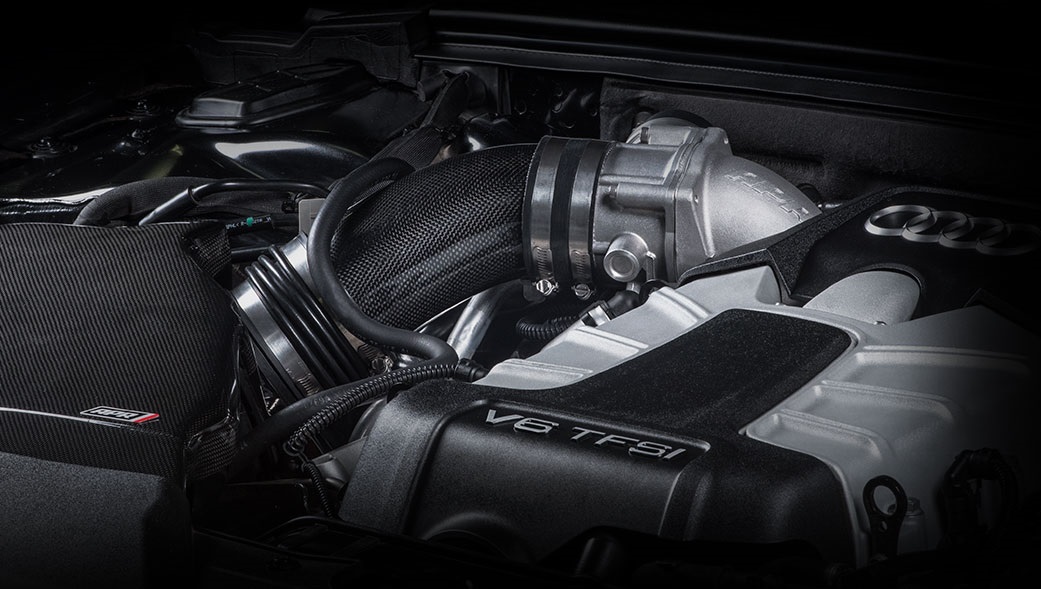

APR 很榮幸的宣布我們又再一次的提高了我們的競爭門檻, 邁向福斯奧迪性能進化的極限! 我們在此推出最新的APR 強化汽門彈簧系統

APR汽門彈簧系統為高性能, 輕量化的升級套件, 以增加汽門控制和根絕汽門浮動等問題所設計製造. APR所設計的這組汽門彈簧系統包含了特殊設計的汽門彈簧和汽門彈簧座, 以確保再保持高水準的汽門控制度下不壓過原廠閥門或是腐蝕鋁製彈簧座. 此系統換來了28%的輕量化和20%高於Golf R的原廠零件硬度, 徹底改善了原廠汽門的弱點.

Key Points:

- Increase valve train control

- 71% weight reduction over OEM Golf R retainers

- 19% weight reduction over OEM Golf R springs

- 20% stiffness increase over OEM Golf R springs

- Eradicates TSI K04 “valve float” issues

- Supports higher revving applications

- Weight saving beehive spring design

- ASTM A877A OTSC round wire steel springs

- 6AL4V American titanium retainers

- 4140 heat-treated chrome molly steel spring seats with black oxide coating

- 29 grams per spring

- 2 grams per retainer

- Compatible with OEM valves

- Spring seats included to protects against aluminum erosion in the head

Valve Springs

Weight reduction, and not necessary stiffness, is absolutely necessary to increasing valve control. The APR Valve Spring utilizes a beehive design that allows for a reduction in mass in not only the spring itself, but also through use of a smaller titanium retainer. The springs feature an ovate wire design that allows for even stress distribution resulting in better control at high RPMs through a resistance of harmful valve float inducing harmonics. The lightweight design also accomplishes accurate valve control without requiring an overly stiff spring which has been proven to snap OEM valves in half. Each valve spring weights 29 grams and represents a 19% weight reduction over the OEM Golf R spring. The result is a highly engineered design that’s simply plug and play!

Weight reduction, and not necessary stiffness, is absolutely necessary to increasing valve control. The APR Valve Spring utilizes a beehive design that allows for a reduction in mass in not only the spring itself, but also through use of a smaller titanium retainer. The springs feature an ovate wire design that allows for even stress distribution resulting in better control at high RPMs through a resistance of harmful valve float inducing harmonics. The lightweight design also accomplishes accurate valve control without requiring an overly stiff spring which has been proven to snap OEM valves in half. Each valve spring weights 29 grams and represents a 19% weight reduction over the OEM Golf R spring. The result is a highly engineered design that’s simply plug and play!

Valve Spring Retainers

Through the use of a beehive design, APR’s Engineers were able to design and supply a valve spring retainer that’s smaller than stock to reduce weight as much as possible. In an effort to offer extreme weight savings, at an additional 71% over the OEM Golf R retainers, American 6AL4V titanium was used for its high specific strength weighing in at only 2 grams each. By offering outstanding weight savings, exceptional valve control characteristic are achieved while only requiring a modest 20% increase in stiffness over the OEM Golf R spring.

Through the use of a beehive design, APR’s Engineers were able to design and supply a valve spring retainer that’s smaller than stock to reduce weight as much as possible. In an effort to offer extreme weight savings, at an additional 71% over the OEM Golf R retainers, American 6AL4V titanium was used for its high specific strength weighing in at only 2 grams each. By offering outstanding weight savings, exceptional valve control characteristic are achieved while only requiring a modest 20% increase in stiffness over the OEM Golf R spring.

Valve Spring Seats

Often an overlooked piece of an upgraded valve train is the valve spring seat. The factory heads are aluminum, and unfortunately increased spring pressure can distort or erode the mating surface overtime as they mate directly to the bare head. To prevent this from happening, APR’s Engineers designed valve spring seats out of 4140 heat-treated chrome molly steel with a black oxide coating. The spring seats are strong enough to withstand pressure from the springs and provide a mating surface that evenly distributes spring load across a larger area than the spring it self, allowing an increased spring rate without negative side effects to the aluminum head.

Often an overlooked piece of an upgraded valve train is the valve spring seat. The factory heads are aluminum, and unfortunately increased spring pressure can distort or erode the mating surface overtime as they mate directly to the bare head. To prevent this from happening, APR’s Engineers designed valve spring seats out of 4140 heat-treated chrome molly steel with a black oxide coating. The spring seats are strong enough to withstand pressure from the springs and provide a mating surface that evenly distributes spring load across a larger area than the spring it self, allowing an increased spring rate without negative side effects to the aluminum head.

Eliminating Valve Float

It’s not uncommon to experience valve float with the OEM valve springs, even below the OEM rev limit. On some applications like the 2.0 TSI, backpressure from the K04 turbocharger has been known to force the exhaust valves open. This has been noticed on vehicles with overly weak OEM valve springs and some with higher miles that have simply lost their stiffness over time.

This issue accompanies misfires commonly above 5000 RPM. In some extreme cases, valves are forced open and the vehicle ceases accelerating any further. A quick datalog of intake mass airflow and boost pressure at wide open throttle will show a sudden rise in boost pressure with an immediate loss of airflow as pressure from the open valves is pushed back into the intake manifold.

On other applications, valve float can begin to occur just beyond the OEM rev limit. While other components, such as higher strength valves are often required for extremely high revving applications, the APR Valve Spring System will eliminate float well beyond the revving constraints set forth by the other components.

| System | Engines | Part Number |

|---|---|---|

| APR Valve Springs, Valve Seats and Valve Retainers – Set of 16 Intake / Exhaust | 1.8T & 2.0T (EA113 & EA888 G1/2) | MS100085 |

| APR Valve Springs, Valve Seats and Valve Retainers – Set of 20 Intake / Exhaust | 2.5 TFSI & 2.5L I5 | MS100089 |

| APR Valve Springs, Valve Seats and Valve Retainers – Set of 24 Intake / Exhaust | 3.0 TFSI & 3.2L FSI V6 | MS100090 |

| APR Valve Springs, Valve Seats and Valve Retainers – Set of 32 Intake / Exhaust | 4.0 TFSI & 4.2L FSI V8 | MS100091 |

| APR Valve Springs, Valve Seats and Valve Retainers – Set of 40 Intake / Exhaust | 5.0 TFSI & 5.2L FSI V10 | MS100092 |

LEAVE A COMMENT

You must be logged in to post a comment.

LATEST POSTS

APR 奧迪 RS Q8 (4M) 電腦程式優化 +

APR 奧迪 RS Q8 (4M) 電腦程式優化 +- 8 9 月, 2021

ERST V40 空力套件

ERST V40 空力套件- 27 3 月, 2020

APR Porsche 保時捷 Panamera (971) 4.0T 電腦程式優化

APR Porsche 保時捷 Panamera (971) 4.0T 電腦程式優化- 16 5 月, 2025

APR DTR8563 三階渦輪系統 (2.5T EA855 EVO)

APR DTR8563 三階渦輪系統 (2.5T EA855 EVO)- 24 3 月, 2025

APR 引擎避震塔強化連桿

APR 引擎避震塔強化連桿- 24 3 月, 2025

MOST VIEWED

APR 奧迪 RS Q8 (4M) 電腦程式優化 +

APR 奧迪 RS Q8 (4M) 電腦程式優化 +- 1451 views

ERST V40 空力套件

ERST V40 空力套件- 3951 views

APR 3.0TFSI 超級節氣門系統

APR 3.0TFSI 超級節氣門系統- 78481 views

APR 2.0TSI MQB (EA888 Gen. 3) 引擎電腦升級

APR 2.0TSI MQB (EA888 Gen. 3) 引擎電腦升級- 26408 views

APR MK7 MQB Golf R/S3 一階電腦程式升級

APR MK7 MQB Golf R/S3 一階電腦程式升級- 13946 views